Published in the Journal: October 2018

Tomatoes are a major crop cultivated across Tamil Nadu. During high production seasons, tomato prices often plummet, and sometimes, farmers struggle even to cover harvesting costs. Processing harvested tomatoes into valuable products ensures income and prevents wastage. Along with converting tomato pulp into food products, seeds can be preserved and sold for a good price. Here are four methods for extracting tomato seeds.

1. Fermentation Method

This method is suitable for small-sized tomatoes with a high seed content. Ripe tomatoes are collected and left in a clay pot for two days to ripen further. Then, they are thoroughly crushed and left to ferment for another two days. Once fermented, the mixture is stirred, causing the seeds to separate and settle at the bottom while the pulp floats. The pulp is removed, and the seeds are washed 7-8 times in clean water, sun-dried, and stored in airtight containers.

2. Alkaline Cleaning Method

For large tomatoes with fewer seeds, this method involves cutting ripe tomatoes in half and scooping out the seed sections using a spoon, leaving the rest of the fruit for food processing. The seed pulp is then soaked overnight in 5 liters of boiling water mixed with 150 grams of washing soda. This separates the seeds, which settle at the bottom. After draining the water, the seeds are washed and sun-dried.

3. Acid Cleaning Method

Known for its speed, this method is used for large-scale seed production. The seed pulp is treated with 30 ml of hydrochloric acid per 12 kg of pulp, which quickly separates the seeds in 15-30 minutes. The seeds are then washed, sun-dried, and stored. This method ensures the seeds retain their color and quality.

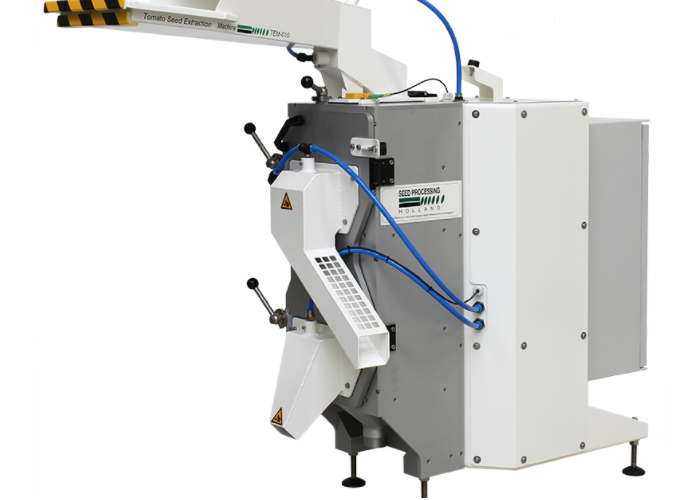

4. Mechanical Extraction Method

This is a simple and efficient method that doesn’t require chemicals. In this method, ripe tomatoes are crushed by a machine, which uses water to separate seeds from the pulp. The water is recycled within the machine, reducing wastage. The machine measures 500x450x1000 mm and can process up to 180 kg of tomatoes per hour, yielding around 1.8 kg of seeds. It operates on a 0.5-1.0 HP motor, costs between 15,000-20,000 rupees, and has an operating cost of just 10 rupees per hour.

Dr. M. Siddharth, Dr. K. Velmurugan, Agricultural Science Center, Kattupakkam, Kanchipuram District